OUR SERVICES

DESIGN / DEVELOPMENT

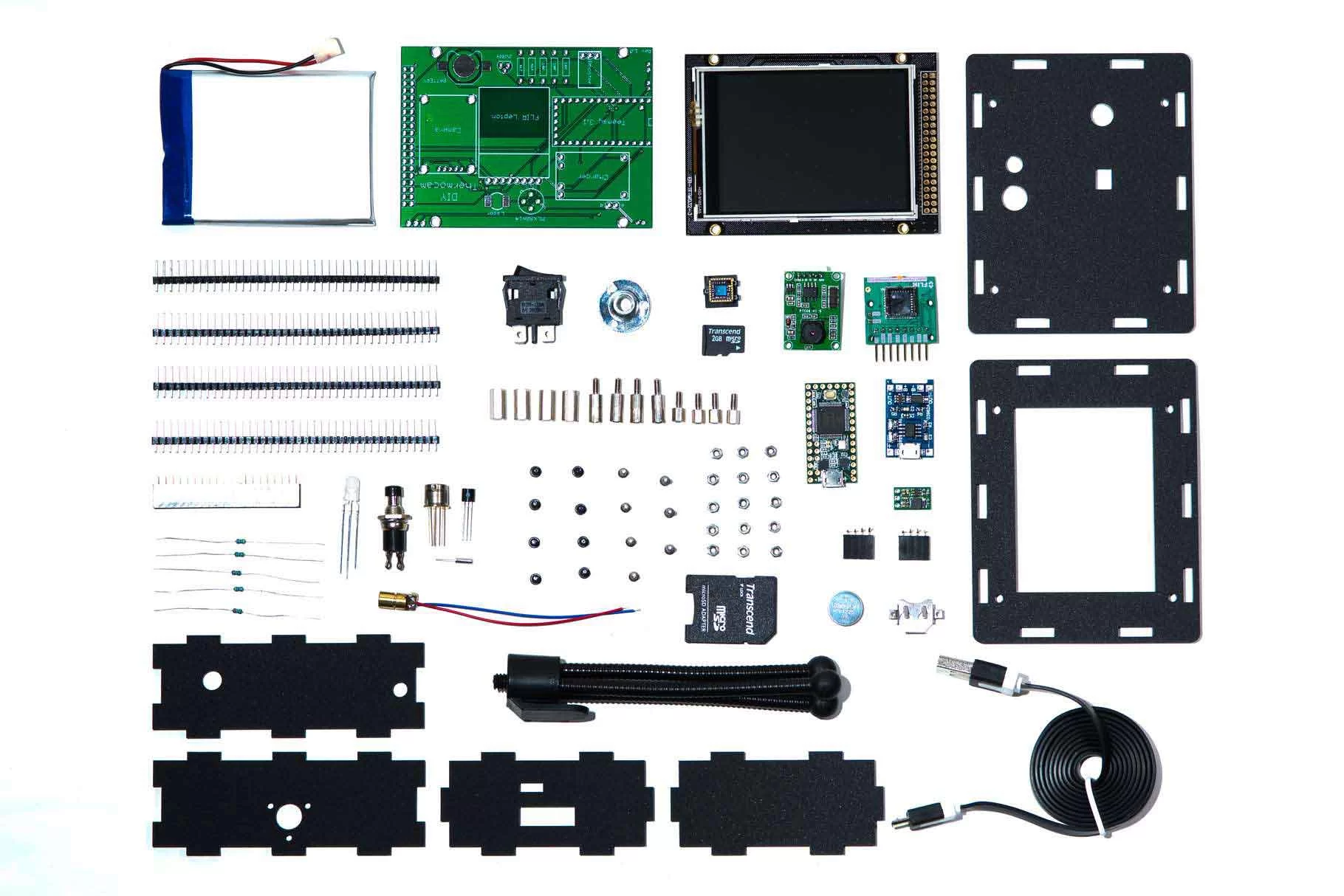

A multi-disciplinary team of experienced engineers and technicians offer their support in all phases of a project, from defining customer specifications and creating a first concept to hard and software development or definition of adequate mounting technologies. Well-stablished project management ensure calculable and controllable development cost.

If you have attempted to create solutions for your product, our engineer will continue to develop where you left off.

Simply send us a circuit diagram along with the necessary parameters and CAD details. Will make the appropriate design and create the layout for the printed circuit board -using Protel Altium or Cadsoft Eagle. in this process we always ensure parts availability, producibility of design and product testability.

OUR RANGE OF ACTIVITIES

CIRCUIT LAYOUT

DEFINITION OF THE MOUNTING AND INTERCONNECTION TECHNOLOGIES

SELECTION OF COMPONENT AND ALTERNATIVE

OPTIMATION OF DESIGN ACCORDING TO COST ,FABRICATION AND TESTING

PROTOTYPING AND SERIES PRODUCTION

ACCELERATED LIFE TEST AND EMC TESTING

IMPLEMENTATION OF REVIEWS

LONG-TIME EXPERIENCE IN MANUFACTURING AND HIGHLY COMPLEX LAYOUT

OPTIMIZATION COMPREHENSIVE TEST CONCEPTS

EXTENDED COMPREHENSIVE CUSTOMER DOCUMENTATION

PRODUCTION / ASSEMBLY

Customer satisfaction is our most primary goal. A motivated and flexible team of engineers, technicians and skilled workers ensure reliable production processes. In this way we provide consistently high product quality, reliability and adherence to schedules, At ARKA-EP investment in the future is not just a catchword. Substantial amounts of money are used each year to modernize production equipment. In parallel to this, care is taken to improve logistics and production processes accordingly.

OUR SERVICES TO YOU

PROTOTYPE AND SMALL SERIES

INDUSTRIAL SERIAL PRODUCTION , TYPICALLY UP TO 100,000 PIECES PER YEAR

MANUAL ASSEMBLY OF COMPONENTS

STORAGE OF MOISTURE-SENSITIVE COMPONENTS IN CONTROLLED ENVIRONMENT

ASSEMBLY – FROM INDIVIDUL COMPONENTS TO COMPLEX SYSTEM

TESTING / QUALITY CONTROL

An important component of our quality management is the common development of the efficient testing system by our team of experts. For this strategy we utilize various type of test units, like automized optical inspection, in-circuit testing or product specific functional testing. For the development of our testing program we put years of experience and know – how to use. Based on technical data you provide for us, we develop the diagnostics software and create the corresponding test systems specifically needed for your product .

WE OFFER THE FOLLOWING TESTING METHOD AND STRATEGIES

CIRCUIT ANALYSIS

DETERMINATION OF TEST DEPTH

DEVELOPMENT OF A TEST CONCEPT

IMPLEMENTATION OF CUSTOMIZED TESTING

OPTICAL TEST METHOD

MANUAL VISUAL INSPECTION

AUTOMIZED OPTICAL INSPECTION

FUNCTIONAL TEST / SYSTEM TEST